Mitigation measures

What noise levels can we expect from REM traffic, and what mitigation measures are planned?

Video capsule: Noise mitigation measures

In this second capsule of a series of three videos, Denis Andlauer, director of operations, presents the different mitigation measures found on the REM network, depending on the types of noise emitted.

Noise in railway environments

Railway noise is made up of different types of noise. It is linked, among other things, to track condition and configuration, and to the type and speed of trains (passenger, freight).

In general, the following types of noise can be encountered:

- Rolling noise, produced by contact between wheel and rail.

- Traction noise, produced by the engine and transmission systems.

- Impact noise, produced by the impact of wheels on the rail junction.

- Squealing noise, which can be produced by passing cars on curves.

- Rumbling noise, which can be produced by the spread of vibrations through a structure.

- Auxiliary noise, produced by air conditioning and heating in particular.

The REM’s case

However, according to analyses carried out by SYSTRA (the expert assigned to the REM project), three main types of noise stand out:

- Rolling noise: This is generated by irregularities in the rail and wheels. These micrometre-sized irregularities, which are needed for trains to stick to tracks, cause the rails, wheels and sleepers (or concrete platform) to vibrate. These elements accumulate noise by vibrating, leading to rolling noise.

- Rumbling noise: This is characterized by low frequencies (deep sound). It is the radiation of a heavy structure, such as an overpass deck, caused by the vibrations spread through it by the passage of a car.

- Station noise: The main sources of fixed infrastructure noise are station systems, such as ventilation, heating, and those connected to the REM power supply.

As explained above, the impact of these types of noise varies according to the environment in which they occur. Nevertheless, there are a number of actions and measures in place to deal with these sources of noise.

Mitigation measures

From the outset of REM’s design phase, particular attention was paid to preventing noise pollution from its components whether rolling stock, stations or tracks.

At-source measures

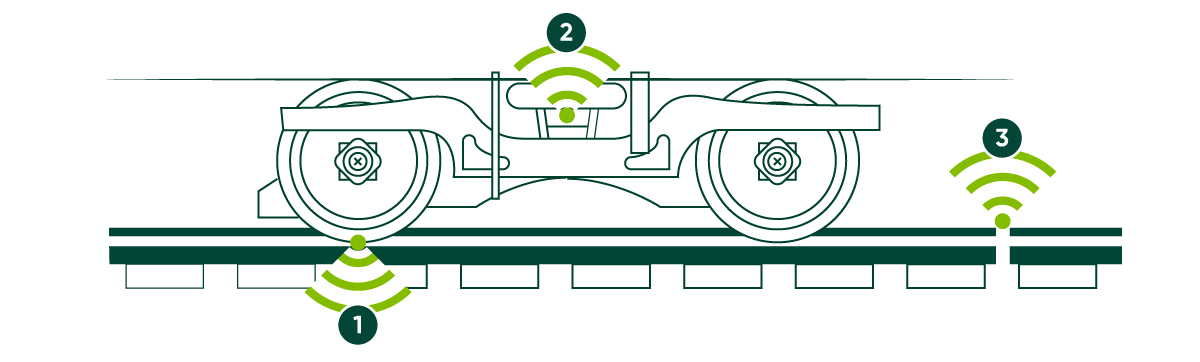

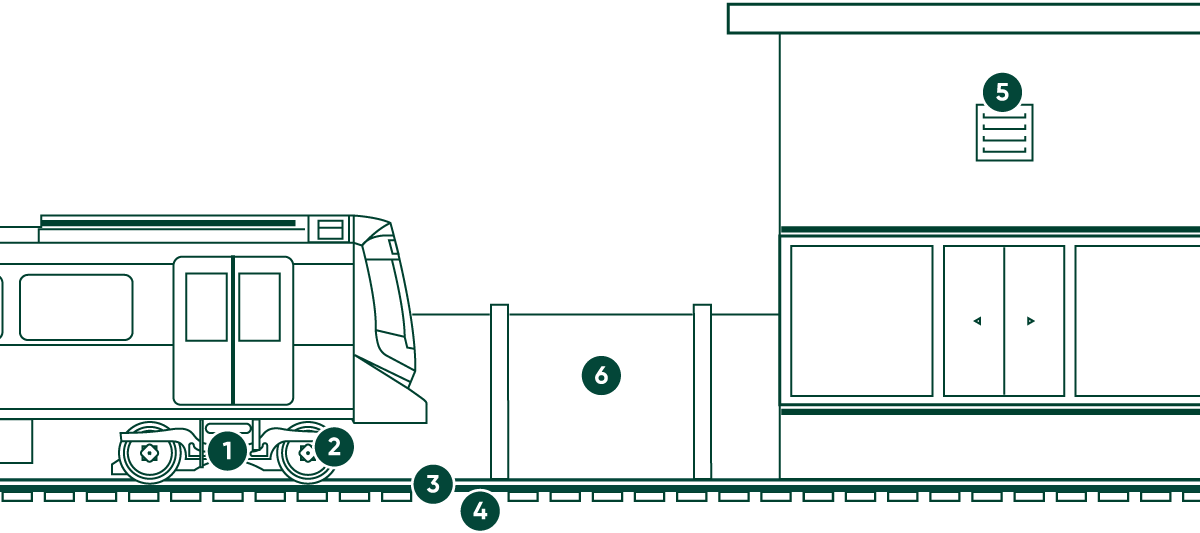

REM cars

REM cars have features that help reduce the noise caused by their circulation:

1. A 100% electric motor to reduce auxiliary and traction noise.

2. Specially treated metal and wheel flange lubricators to prevent curve squeal.

The tracks

The tracks themselves have also been designed to avoid certain noises generated by contact between the rails and car wheels.

3. These include rail welding, which not only improves ride comfort and reduces maintenance costs, but above all eliminates impact noise and vibration at rail joints.

4. Rubber supports were installed, in some locations, under the track to reduce rumbling noise.

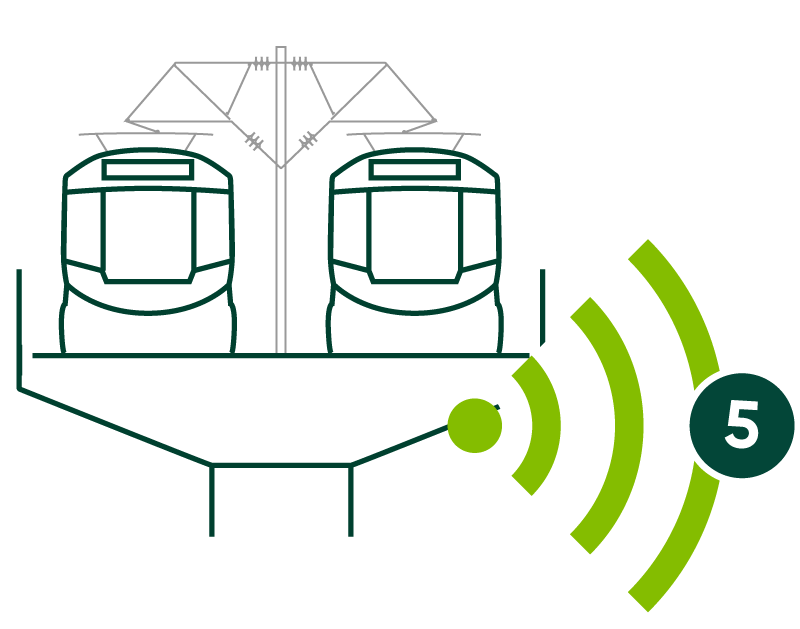

Fixes infrastructures

As for fixed infrastructures, mitigation measures have also been incorporated into the design and construction of buildings, such as:

5. the installation of silencers on ventilation equipment.

6. The construction of artificial obstacles such as barriers.

Complementary measures

In addition to the measures taken to reduce noise at source from the REM, further measures have been added to attenuate noise from the passage of the REM.

These complementary measures mainly involve the installation of noise barriers along residential areas and sensitive receptors at various points on the network.

Maps of noise barrier locations by sector:

REM noise barrier

REM noise barrier

Inside REM noise barriers

Inside REM noise barriers

Noise barriers are mostly made of white, 100% PVC prefabricated panels installed on galvanized steel poles. They have acoustic insulation inside that absorbs sound and prevents it from bouncing back. A second type of noise barrier, made of multiple stone-filled metal mesh cages (gabions) with a concrete core, is part of the network and further helps reduce the noise impact.

In addition, a maintenance program for the tracks and rolling stock is in place and will continue throughout REM operations. It includes track grinding and wheel reprofiling to reduce rolling noise.

Measure enhancements

The types of infrastructure in place, such as overhead tracks and certain technical equipment, have influenced noise behaviour. As a result, mitigation measures have been improved where required:

- Dynamic absorbers have been installed directly on the tracks to dampen the noise generated by the vibration of passing trains and reduce rolling noise.

- A gabion noise barrier was added at the top of the embankment in the Town of Mount-Royal area in addition to new sections of prefabricated panel noise barriers on Île-Bigras, in Deux-Montagnes, in Town of Mount-Royal and in the Saint-Laurent borough.

- A maintenance operation was then initiated, including wheel reprofiling of the rolling stock as well as track grinding. By combining these two actions, contact between the wheels and tracks was smoothed as much as possible to reduce rolling noise.

An enhancement that was made possible through:

- Noise measurements made prior to the launch of the REM and acoustic modelling that determined its projected noise impact.

- Analyses conducted during REM operations in order to understand the factors causing the gap between the projections and reality, and to identify appropriate mitigation measures to reduce this gap.

This demonstrates the importance of the established acoustic monitoring process, which includes noise analyses performed before, during and after commissioning, in each environment through which the REM passes.