Five innovative techniques to build the REM

Building a 67 km light rail metro involves serious challenges, including that of working quickly, while respecting the environments crossed. The REM route passes through many different environments: waterways, a tunnel in the heart of downtown, protected wetlands, residential neighbourhoods and even below YUL runways!

Here are five examples of innovative methods implemented to optimize the work and overcome major construction challenges.

1. The umbrella technique: repairing from within to avoid a major closure

📍 Mont-Royal Tunnel sector, McGill station

To cross downtown, the REM will use the Mont-Royal railway tunnel, where a major modernization is now underway.

The work in progress includes rebuilding the vault that supports the southern part of the tunnel, near McGill station. Because of deterioration, it was decided to demolish part of the double arch and replace it.

The engineers devised an innovative solution to demolish the old structure and rebuild the arch without causing a major closure – we’re in the very heart of downtown here, and 20-storey skyscrapers tower over the tunnel!

An umbrella method was adopted. These are the steps:

- To begin, a temporary retaining wall was created by reinforcing the structure above the double arch with casings. The name “umbrella method” comes from the half-circle formed over the arch.

- The retaining wall created allowed teams to move in to excavate and demolish the damaged wall of the double arch.

- Next, the casings were removed to add steel arches to reinforce the structure.

The speed of this solution allowed us to address the deterioration without a major delay in the work schedule.

Installation of casings – summer 2021

Installation of casings – summer 2021

Demolition of the double arch – summer 2021

Demolition of the double arch – summer 2021

2. Counterweight launching method: building an incrementally launched bridge

📍 North Shore sector

To connect the REM route between Montréal and Îles-Laval, new railway bridges were built using a method rarely seen in Québec until now: an incrementally launched bridge.

Usually, constructing a bridge across a waterway requires jetties (temporary workspaces built on the water to create platforms and docks) on which equipment can be installed. With an incrementally launched bridge, sections are built first on one of the two shores, then pushed out over the water onto the previously installed piers. No jetties are needed in the river. This method helped compensate for the particularly strong current in the construction area, speeding building of the bridge.

Bridge over the Rivière des Prairies (connecting Montréal and Laval) during construction using the counterweight launching method – summer 2020.

Bridge over the Rivière des Prairies (connecting Montréal and Laval) during construction using the counterweight launching method – summer 2020.

3. Launching gantries: an elevated structure in record time

📍 West Island sector

A launching gantry is an impressive 105 metre machine that was used for the first time in Québec to build the REM’s elevated structure. To hasten work, two launching gantries, nicknamed Anne and Marie, were mobilized on the project in different places along the route to allow construction at the same time.

Anne and Marie built 16 km of elevated structure, mainly in the West Island sector.

Anne and Marie built 16 km of elevated structure, mainly in the West Island sector.

Positioned between two piers, the gantry raises segments (concrete sections weighing 50 tonnes each) one by one to assemble them, ultimately forming what is called a “span”.

While used widely elsewhere, this method is relatively uncommon in Québec. The advantage? Launching gantries enable much faster construction: on average, just two days is needed to assemble a span, compared with three weeks using traditional methods.

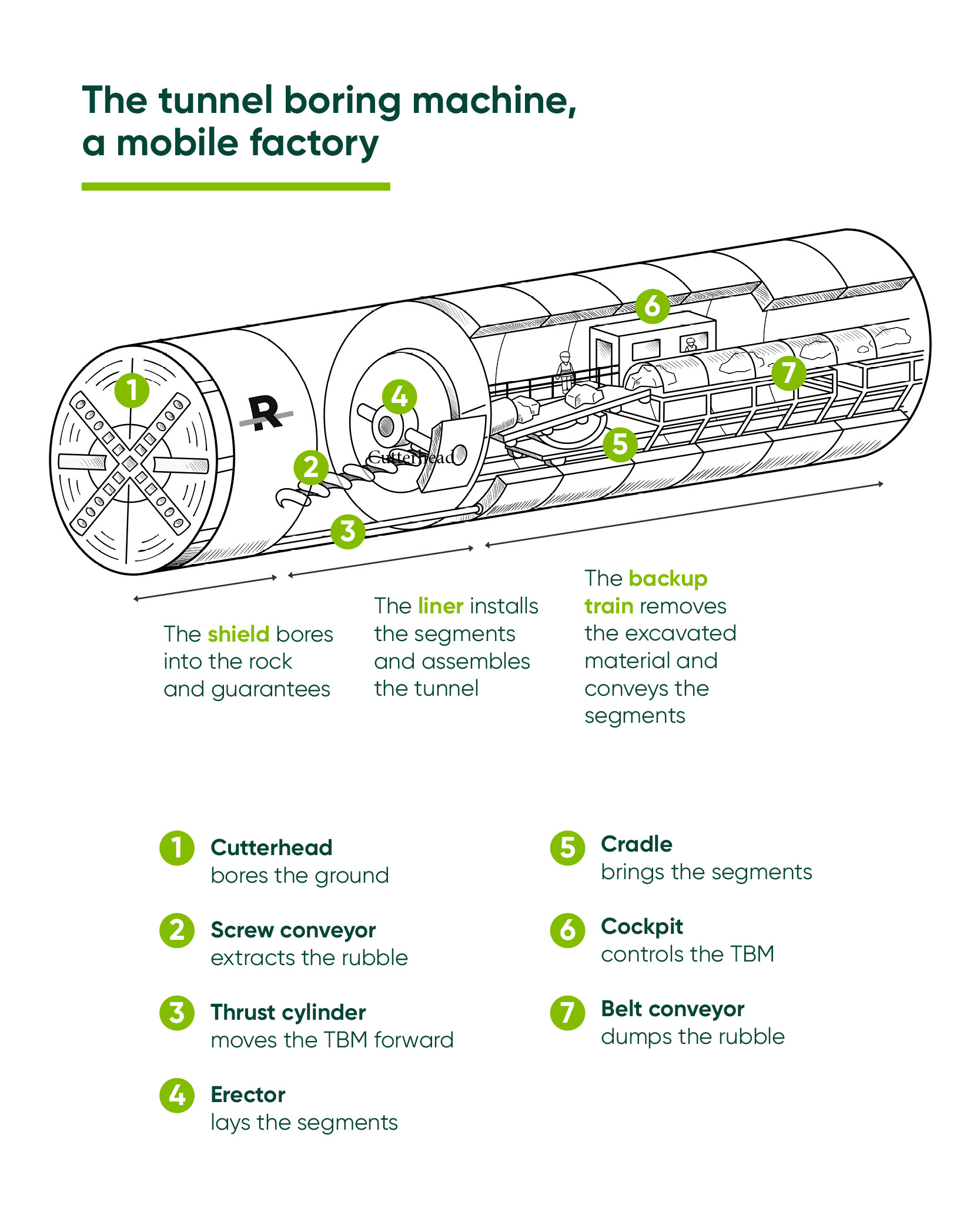

4. The tunnel boring machine: another first in Québec

📍 Airport sector

The REM will travel between the Technoparc sector and YUL-Aéroport-Montréal-Trudeau station through a 3 km tunnel, 30 metres below ground. Given the very complex soils in this area, and the need to protect the environment and existing infrastructures, only one technology was up to the challenge: a tunnel boring machine.

This impressive machine offers the advantage of performing several tasks: it can simultaneously drill rock, assemble tunnel walls and remove the waste and earth generated as it passes. The tunnel boring machine finished its work in the summer of 2022, after drilling and installing a 2.5 km tunnel.

5. SOGUN: projection serving concrete teams

📍 Mont-Royal Tunnel sector

The REM project is fertile ground for innovation! To increase the efficiency of the many shotcrete tasks to be done in the Mont-Royal Tunnel, the SOGUN method was used so teams could determine the exact thickness of concrete applied.

The system uses a Lidar (Light Detection and Ranging) sensor and thousands of laser beams to digitize the tunnel surface. In under a minute, it creates a 3-D scan, processes the data and compares the actual surface with that of the design. Then, the laser light projection system shines different colours onto the tunnel walls to show where work is needed. Along with highlighting small differences on the tunnel walls, numbers indicate how much concrete should be sprayed or removed. This whole system is connected to an on-board computer that can calculate the exact amounts needed by comparing in real time how the tunnel is progressing against the design file, which is the final result desired.