Launching gantries: an unprecedented construction method in Québec

If you’ve been on Highway 40 recently, you’ve undoubtedly noticed a huge yellow beam in the air near Fairview Pointe-Claire. This enormous machine is called a “launching gantry,” and is assembling the REM’s elevated structure, piece by piece.

It’s job is to build the REM structure that extends some ten kilometres along the highway, between West Henri Bourassa Boulevard to Sainte-Anne-de-Bellevue.

To move things forward even more quickly, there are in fact two launching gantries working in tandem on the elevated structure:

- The first launching gantry, nicknamed Marie after Marie Curie Street in the Technoparc, will assemble the elevated structure between the Technoparc and the midway point, Fairview Pointe-Claire.

- From that midway point, the second launching gantry will build the remaining section of elevated structure, up to Sainte-Anne-de-Bellevue, which is where it gets its nickname – Anne.

View the path that launching gantries Marie and Anne will travel. Nicknaming large machines is a tradition in the construction industry.

A first in Québec

This is the first time launching gantries have ever been used in Québec. The principle: a long beam is installed between two columns. Marie and Anne are each 105 metres long and can support up to 550 tons!

Photo credit: @ashrafgiraffe

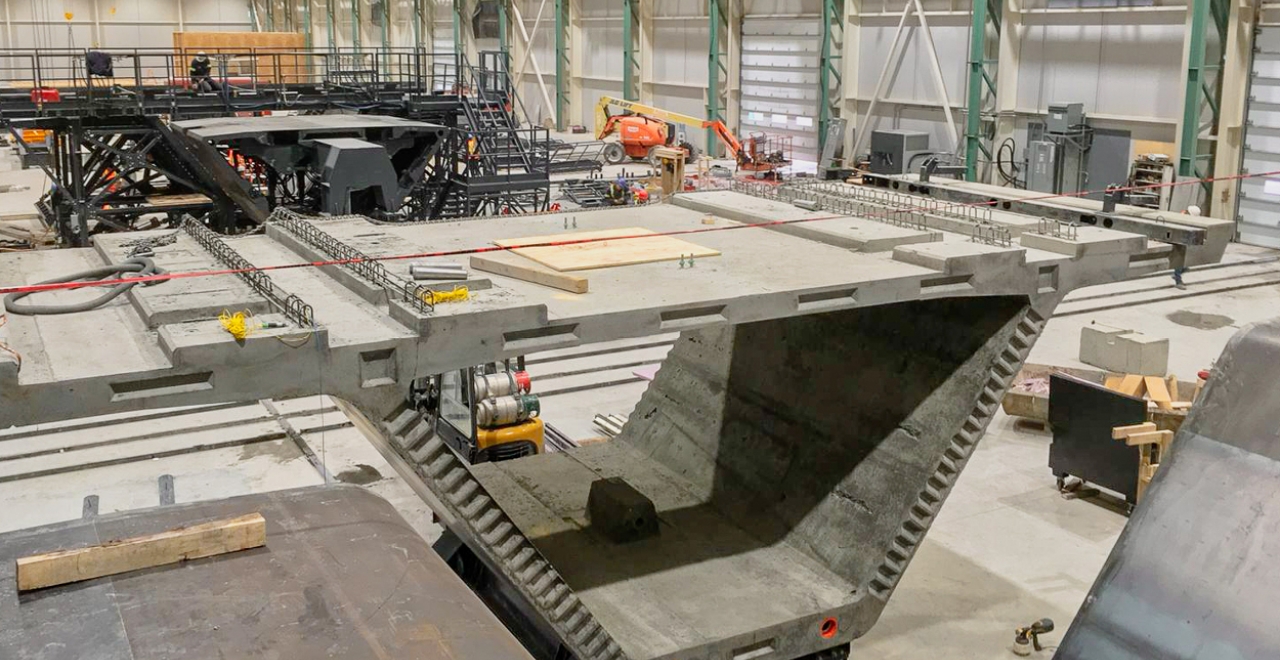

These super-powerful beams raise the prefabricated segments (made of concrete, weighing about 50 tons each) and slide them up against one another to form the deck on when the REM’s rail cars will run.

That’s why they're called “launching gantries” – because the prefabricated segments are “launched” one after the other.

It’s quite an impressive construction method and ensures things to move forward very quickly. On average, it takes two days to erect one span, that is, to cover the distance between two columns (30 to 40 metres).

Once the span is complete, the beam is moved forward to the next two columns, and the process is repeated. It will take Marie and Anne three years to build the entire 14.5-km section of elevated structure.

![]()

Construction of the elevated structure, step by step

![]()

REM construction on the West Island

- 2 launching gantries: LG-1 Anne and LG-2 Marie

-

4 stations

-

14.5 km of elevated structure

-

9.30 m wide (deck)

-

366 spans

-

4,102 voussoirs (prefabricated segments)

-

Commissioning in 2024

For more technical information, download our media briefing presented on June 18, 2019.