The REM And The Challenges Of Winter

Winter is coming to Quebec! With the first snowflakes on the ground in the Greater Montreal area, here is an overview of the elements that were put in place to allow the REM to run outdoors.

An Operational Plan To Deal With The Winter Weather

As is the case for motorists when winter returns, there is always a period of adaptation to driving during the first snowfall. Although we have learned a lot in previous winters, the REM also needs to adapt to changing temperatures, especially in this first year of service.

In order to be well prepared, we have carried out various tests over the past few years:

1- Static Tests In Climatic Chambers

From November to December 2020, static tests were conducted with a REM car in one of the world's best climate chambers in Vienna, Austria. The objective: to demonstrate the validity of the cars' design by verifying that the comfort of future passengers would be optimal and that all types of climatic conditions would not impact critical functions.

Copyright: Alstom/Planimonteur-L.Trottier

Copyright: Alstom/Planimonteur-L.Trottier

2- Dynamic Tests Of The Metro System In Real Conditions

Over the past few winters, crews have conducted dynamic tests, with a running REM, first on a short 3.5-kilometre segment and then on the entire South Shore section in 2022 and 2023.

Copyright: JF Savaria

Copyright: JF Savaria

Use Of Snow Brakes

Like other transit systems in major cities around the world, the REM is equipped with snow brakes. The presence of platform screen doors in our stations requires great precision when each car arrives at the station and has to stop at the doors. One of the lessons learned during the dynamic testing period is the need to apply, during storms and depending on the amount of snow received, a slight pressure on the brakes in order to dissolve the snow that could accumulate between the shoe and the wheel. This allows us to ensure the fine precision required.

During the first days, technical teams will be deployed on the ground to monitor the situation. They are recognizable by their GPMM and/or REM clothing. Their presence contributes to the smooth running of operations.

Attention to all users: when the light pressure of the brakes is applied to the wheels, it is normal that the contact between the two surfaces can give off an odor similar to that of burning.

Snow Removal From The Tracks

As for snow removal from the tracks, a set of strategies were planned: frequent passage of cars to avoid snow accumulations, specialized maintenance equipment to remove snow from the tracks, and deployment of the switch heater system.

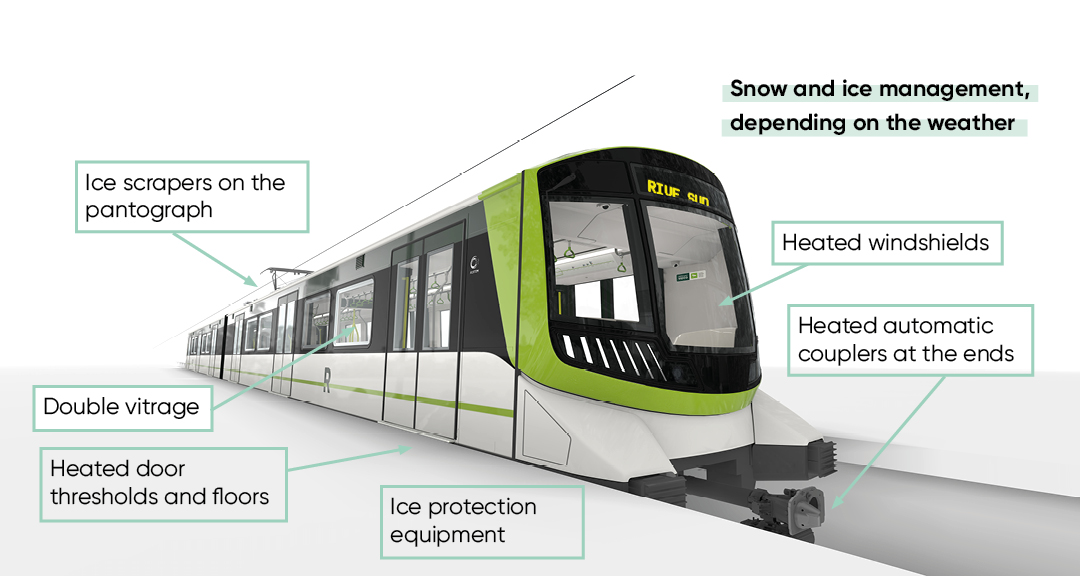

A Design For Quebec Winters

The design of the car, an Alstom Metropolis model, has been specially adapted to deal with the climatic context of Greater Montreal.

The main adaptations concern the major components of the 212 cars ordered from Groupe PMM, in particular:

- Double glazing, for enhanced thermal insulation;

- A heated front windshield to prevent snow and ice build-up on the glass;

- A high-performance heating/cooling system;

- Door sills and heated floors;

- Heated automatic couplers. These couplers, at the ends of the trains, have the function of "linking" two trains together in order to create 4-car trains;

- A specific selection of materials to go under the cars (bogies, sand pits, etc.);

- A snowplow installed at the front of the trains to facilitate the clearing of snow accumulations;

- An ice scraper on some pantographs. This scraper will remove ice build-up from the catenary used to supply electricity to the system.

Keeping You Warm In The Network

Both in the stations and in the cars, features are planned to ensure the comfort of users during the winter.

Copyright: JF Savaria

Copyright: JF Savaria

The cars are equipped with various features allowing optimal warmth and comfort for the people on board. The heating blocks have been reinforced and the underfloor heating will allow the evacuation of ice and snow that users bring in with them. In the stations, the buildings are heated and equipped with platform screen doors that minimize heat loss between the stations and the car.

Copyright: Alstom/C-Fleury

Copyright: Alstom/C-Fleury