The REM electrical power supply

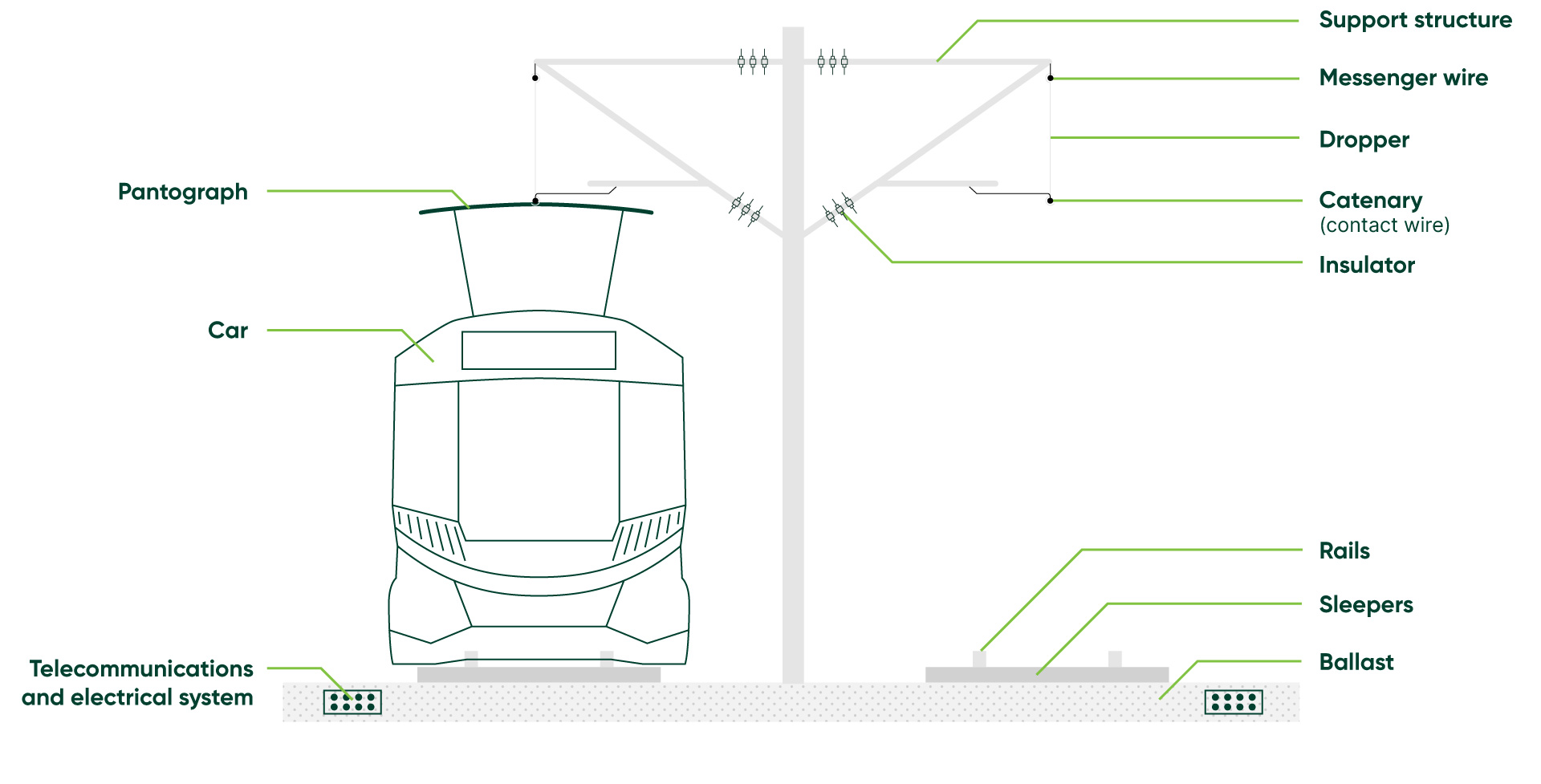

Specifics of the catenary system

The REM is a 100% automated electric light metro that will run through Greater Montréal 20 hours a day, 7 days a week. Since it runs on electricity it will generate no greenhouse gases while in operation. The electric fuelling system will have to be suitable for a transportation network that runs below ground, at ground level and above ground, even in our harsh Québec winters.

The different options for fuelling an electric light metro network

There are two possible options: a third rail and a catenary system (rigid or flexible).

Third rail

Contact with a rail close to the running rails

Rigid or flexible catenary system

Copper or aluminum conductors above the tracks, capturing current by pantograph [overhead tension wire]

Several criteria were considered when we looked for the best solution and compared the options; each one had its advantages and disadvantages.

| Criteria | Flexible catenary | Third rail |

|---|---|---|

| Maximum running speed | Favourable | Favourable |

| Weather conditions | Limited | Unfavourable |

| Electrical chacteristics | Favourable | Limited |

| Route | Favourable | Limited |

| Operations and maintenance | Limited | Limited |

| Urban integration | Unfavourable | Favourable |

| Staff security (maintenance) | Favourable | Limited |

| Experience in snowy terrain | Favourable | Unfavourable |

The third rail will not work in our Québec winters

As its name indicates, this is a third rail laid close to the running rails that transmits power (traction) to the trains along the whole track. Being close to the rails, the third rail is easier to fit into the urban landscape because it is less visible than the catenary.

Vancouver's SkyTrain, powered by third rail

Vancouver's SkyTrain, powered by third rail

However, since the third rail is on the ground, it is particularly vulnerable to significant accumulations of snow and ground frost. When part of the third rail gets covered by ice or snow it can short circuit and interrupt the electric feed to the vehicles. The cars will not be able to run until the snow- or ice-covered portion of the rail has been cleared. Although there are ways to clear the snow, when they are inserted between operating vehicles they cause major slowdowns, sometimes even a temporary halt.

At this time no city in the world with weather like Montréal’s uses a third rail to fuel a light rail transportation system with part of its tracks outdoors.

Catenary: the REM’s choice for electric fuelling

Catenary involves a set of wires above the tracks designed to provide electricity to the cars. The pantograph captures the electric current from the catenary and feeds it directly to the cars.

The pantograph is an “arm” attached to the car roof; it captures the electric current by rubbing against the catenary.

Catenaries come in different configurations: tramway, flexible and rigid. The REM did not choose the tramway configuration because its maximum operating speed is much lower than the other two: 70 km/h compared to 200 km/h for the flexible and 120 km/h for the rigid catenary.

Why choose the catenary system?

It is the safest, because the feeder mechanism is above ground and therefore not accessible to the public and at a safe distance for the workers. It is the most reliable solution in light of our winter weather, even though it is still quite a challenge to operate a public transit system in those conditions. The electric fuelling system for the REM and its cars has had to be specially adapted for our climate.

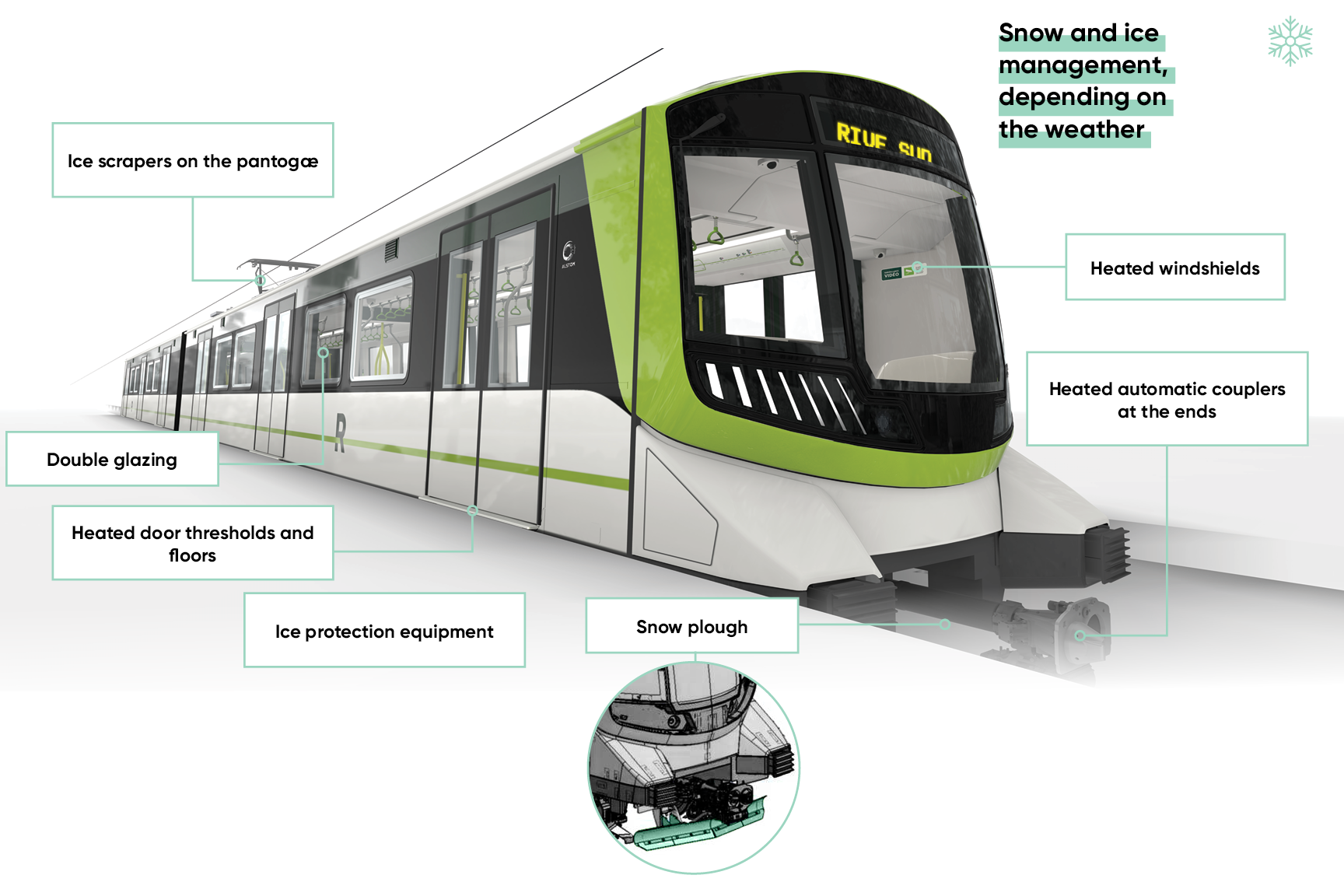

Ready for Montréal winters

Operating an outdoor transportation system in winter is a challenge for any vehicles - buses, métro, tram, etc. In order to stand up to Montréal winters, the REM car pantographs have been equipped with scrapers to clear accumulations of ice off the catenary. The cars will also have snowploughs for safe contact between the rails and the car wheels. That snow clearing method would not suit a third rail, because it would pile the snow up over it. All REM cars come with a lot of equipment to confront winter hazards. Find out more about this topic by reading our feature on REM and the winter.

Cover photo of the article : © Alstom / C. Fleury