Follow-up and results of actions underway to minimize REM noise

In this news item, we follow up on actions taken to mitigate the impact of noise generated by the passage of the REM. We explain the analyses carried out by SYSTRA, an independent specialized firm in the field, and the preliminary results following the implementation of measures to reduce noise from the REM in certain sectors.

Context and reminder

When REM cars began to run more intensively in 2023, a noise impact was noted in some areas between Central and Île-des-Soeurs stations.

Our team commissioned the international acoustics experts at SYSTRA, who began work last September to better understand the situation and find the best solutions to implement in the right places to reduce the REM’s noise level.

SYSTRA’s mandate was twofold:

- Expliquer le phénomène acoustique (le bruit plus élevé que prévu dans certains secteurs) et proposer les solutions adaptées permettant d’atténuer ce bruit;

- Analyser si les mesures mise en place ont un impact sur la réduction sonore lors des passages des voitures du REM.

When the first part of the mandate was completed, a technical report on the noise caused by the passage of REM cars between Île-des-Sœurs and Griffintown was posted on our website. Consult it here: Documentation | REM.

Public meetings were also held in Île-des-Sœurs, Pointe-Saint-Charles and Griffintown. Meeting reports are available here: Événements | REM

Analysis of results

Sound monitoring

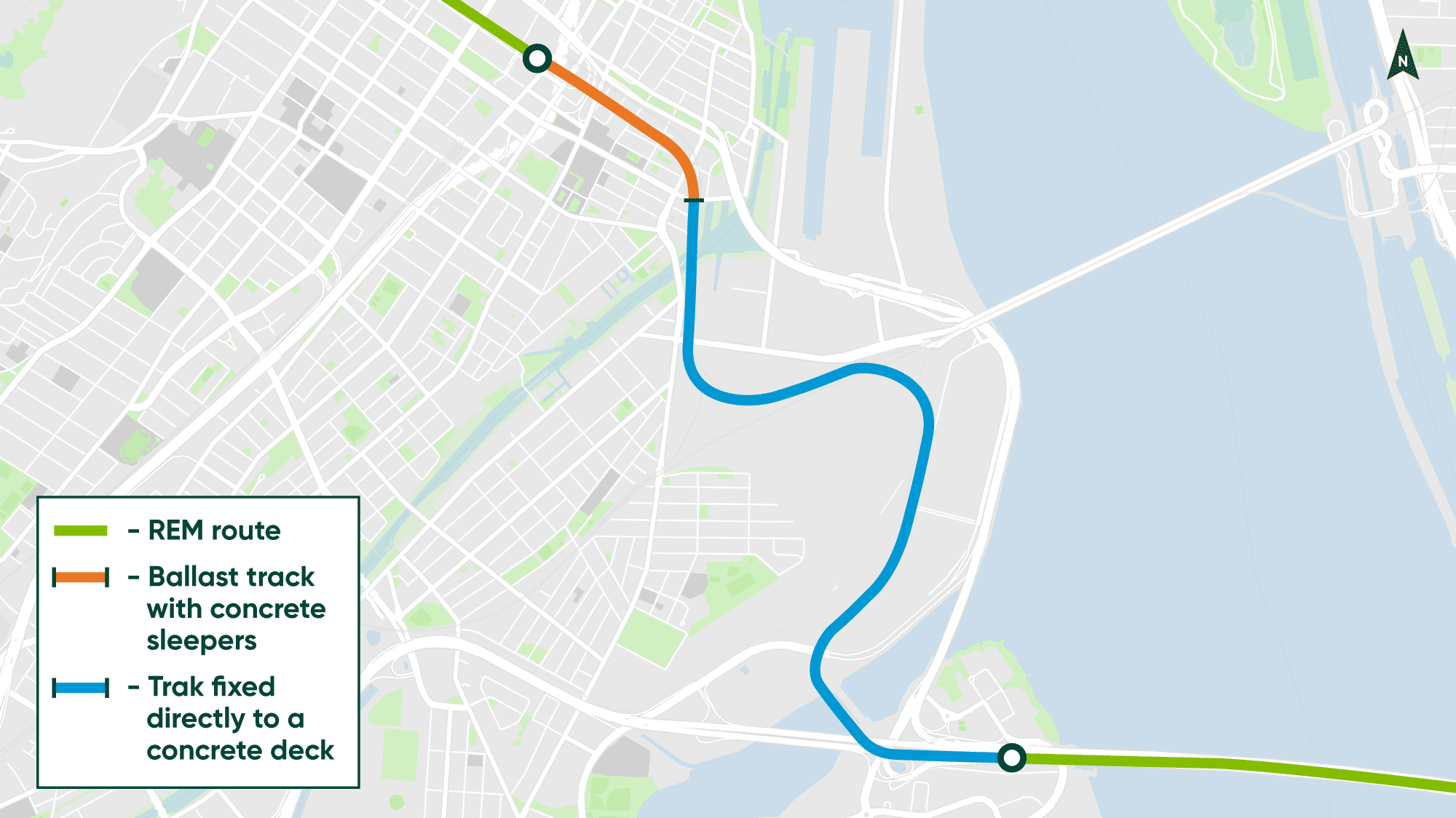

To measure the real impact of the implemented solutions, the teams installed sound level meters at key locations in the target area. There are two types of tracks on the targeted REM segment: ballasted track with concrete sleepers and track fixed directly to a concrete deck. As noise at source is different on these types of installations, sound level meters were placed to measure the results in both target contexts. Sound monitoring will continue throughout 2024.

Map of the two track types

Map of the two track types

The data was measured at the source, following the ISO 3095:2013 standard for Acoustics—Railway applications—Measurement of noise emitted by rail-bound vehicles.

This technique has two advantages:

- The microphone is positioned close enough (7.5 meters) to consider only the noise originating from the train and the track. Consequently, it allows for a more precise quantification of the reductions achieved by solutions without being affected by surrounding noise sources (such as road traffic noise).

- By adhering to standard conditions, we can compare results with other scenarios or detect acoustic performance reductions before they become noticeable to residents.

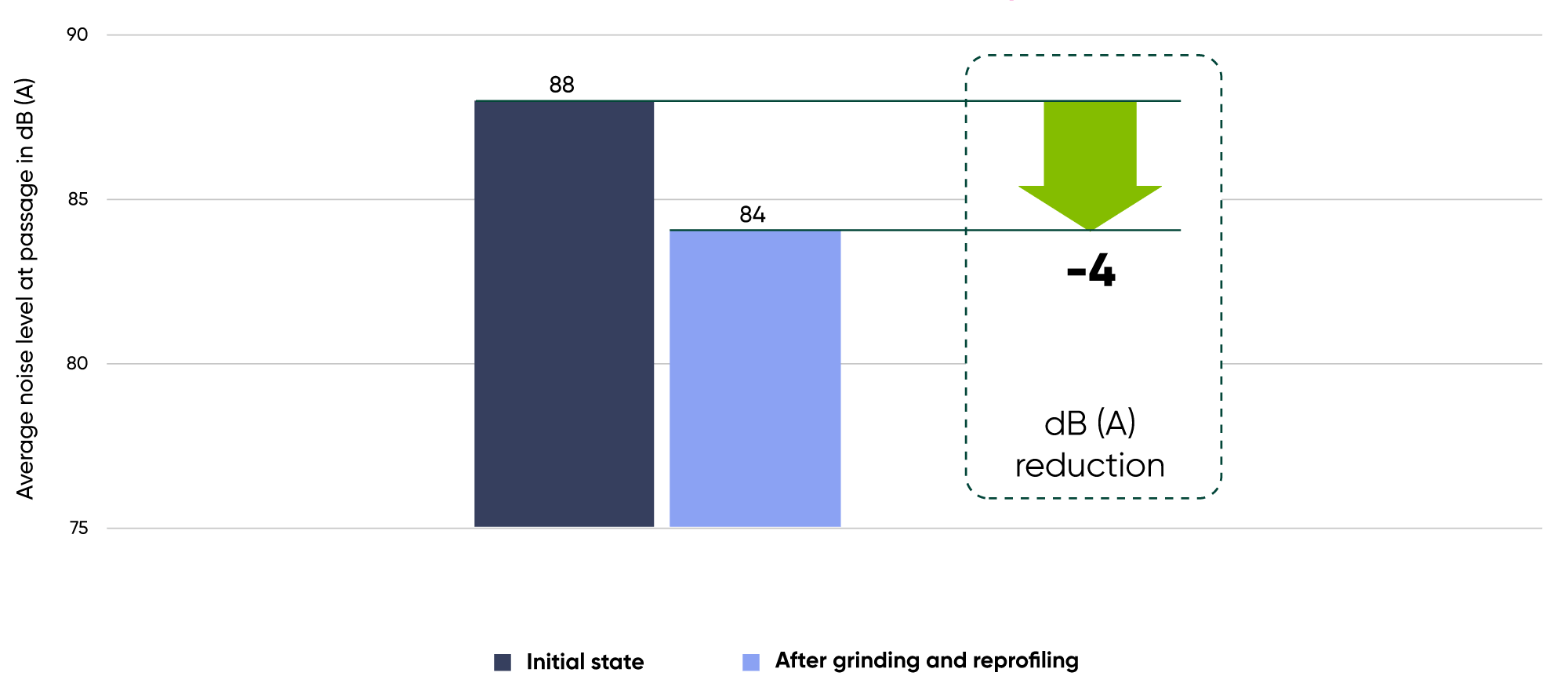

Ballasted track with concrete sleepers

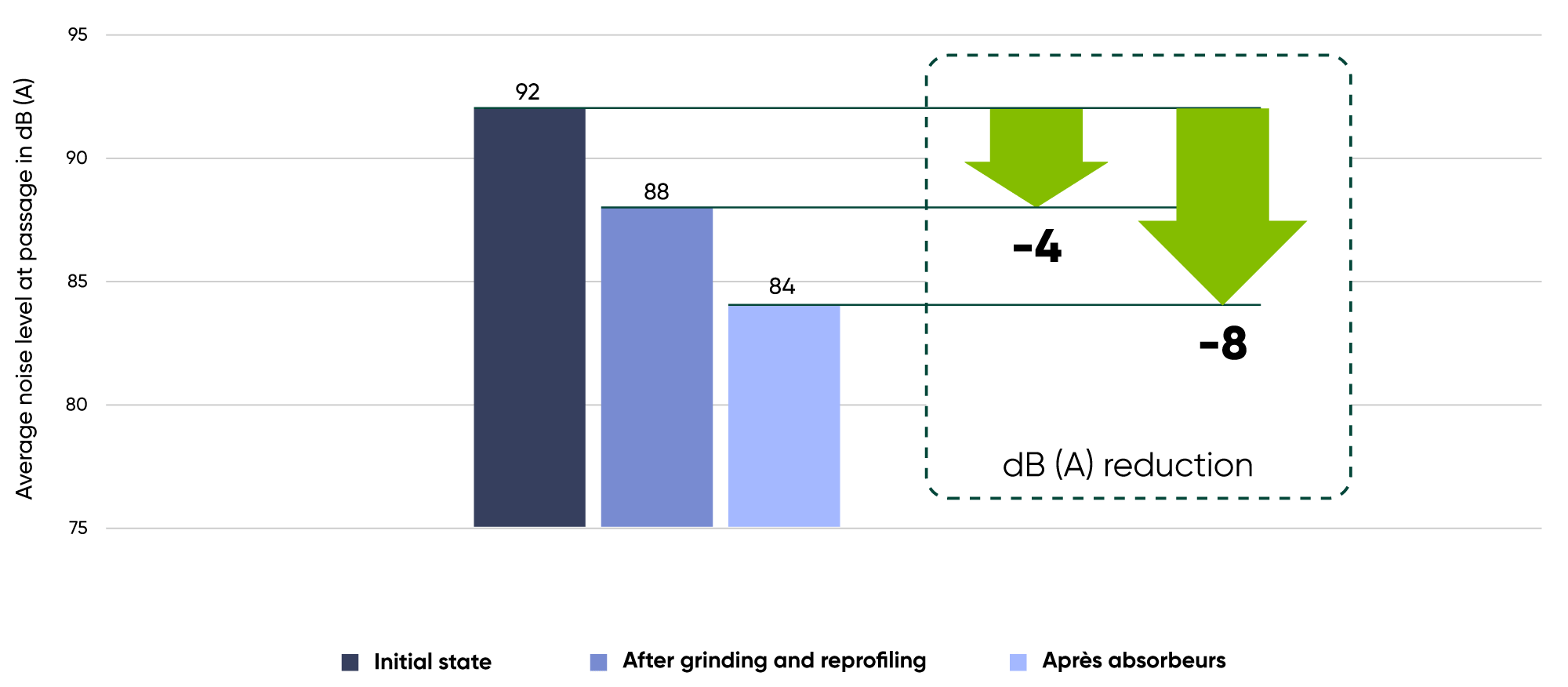

On the sections of the REM route that are ballasted with concrete sleepers, grinding and reprofiling have resulted in a 4 dB(A) reduction in trackside noise.

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels.

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels.

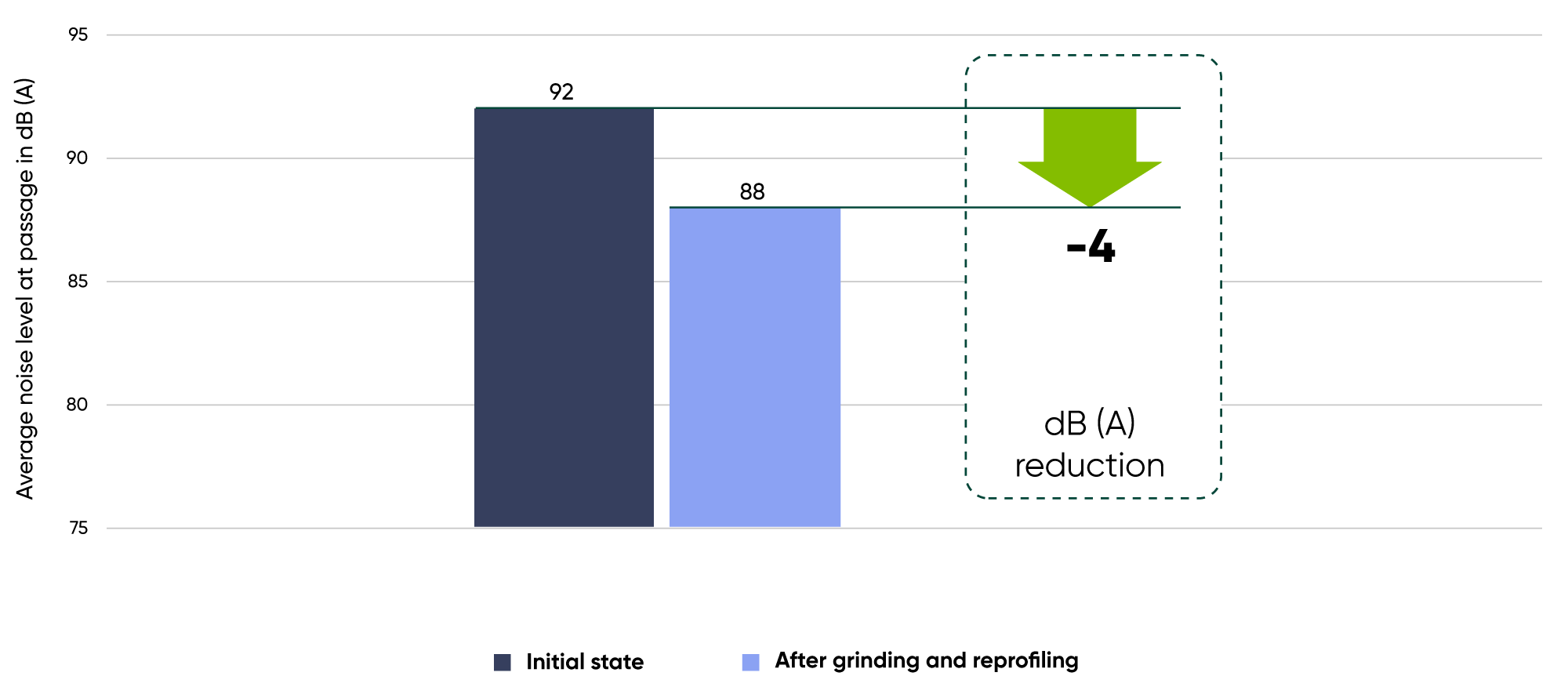

Track fixed directly to a concrete deck

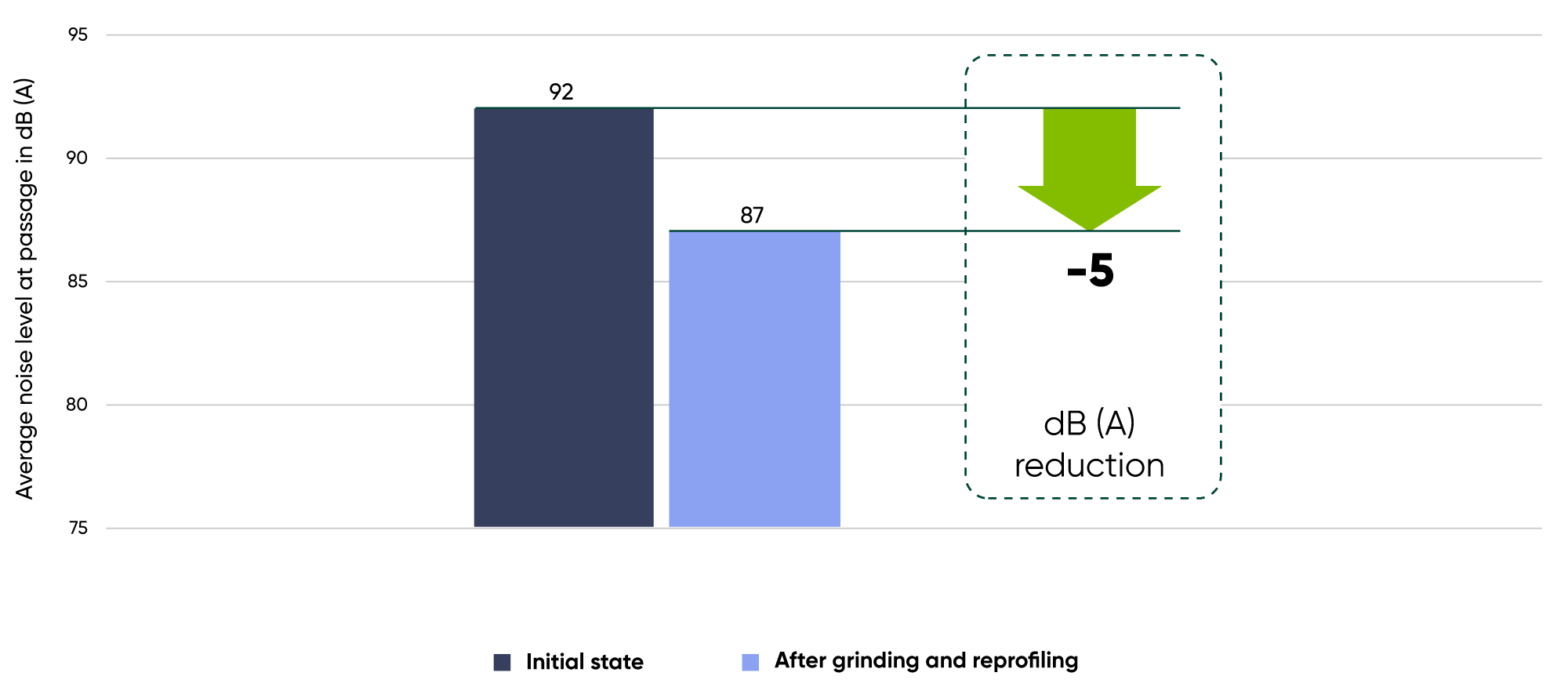

On the sections of the REM route that are elevated on tracks fixed directly to a concrete deck, grinding and reprofiling have reduced trackside noise levels by between 4 and 5 dB(A).

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels – Griffintown/PSC

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels – Griffintown/PSC

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels – Marc Cantin/PSC/Île-des-Sœurs

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels – Marc Cantin/PSC/Île-des-Sœurs

When the contribution of the dynamic absorbers is factored in, the reduction in trackside noise level reaches 8 dB(A), i.e. an additional reduction of 4 dB(A) following installation.

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels, and after installation of dynamic absorbers – Griffintown/PSC

Average trackside noise level as the REM passes before and after grinding and reprofiling the wheels, and after installation of dynamic absorbers – Griffintown/PSC

Where does the noise come from?

Two types of noise were coming from the analyzed area:

Rolling noise

By “rolling noise,” we mean all the noises caused by contact between the wheel and the rail.

Rumbling noise

“Rumbling noise” is the result of vibrations generated by the passage of REM cars over a heavy structure, such as an overpass. The heavy structure then emits a low-pitched sound, at low frequency.

Solutions identified

Reducing noise at source is the best strategy for reducing the impact of noise on local residents, whether they live in high-rise condos or in housing at track-level. The identified measures of dynamic absorbers and specific acoustic maintenance (reprofiling of wheels and acoustic grinding) meet this requirement.

Once these mitigation measures had been installed, SYSTRA carried out noise monitoring to confirm the results of these actions, the data for which is presented above.

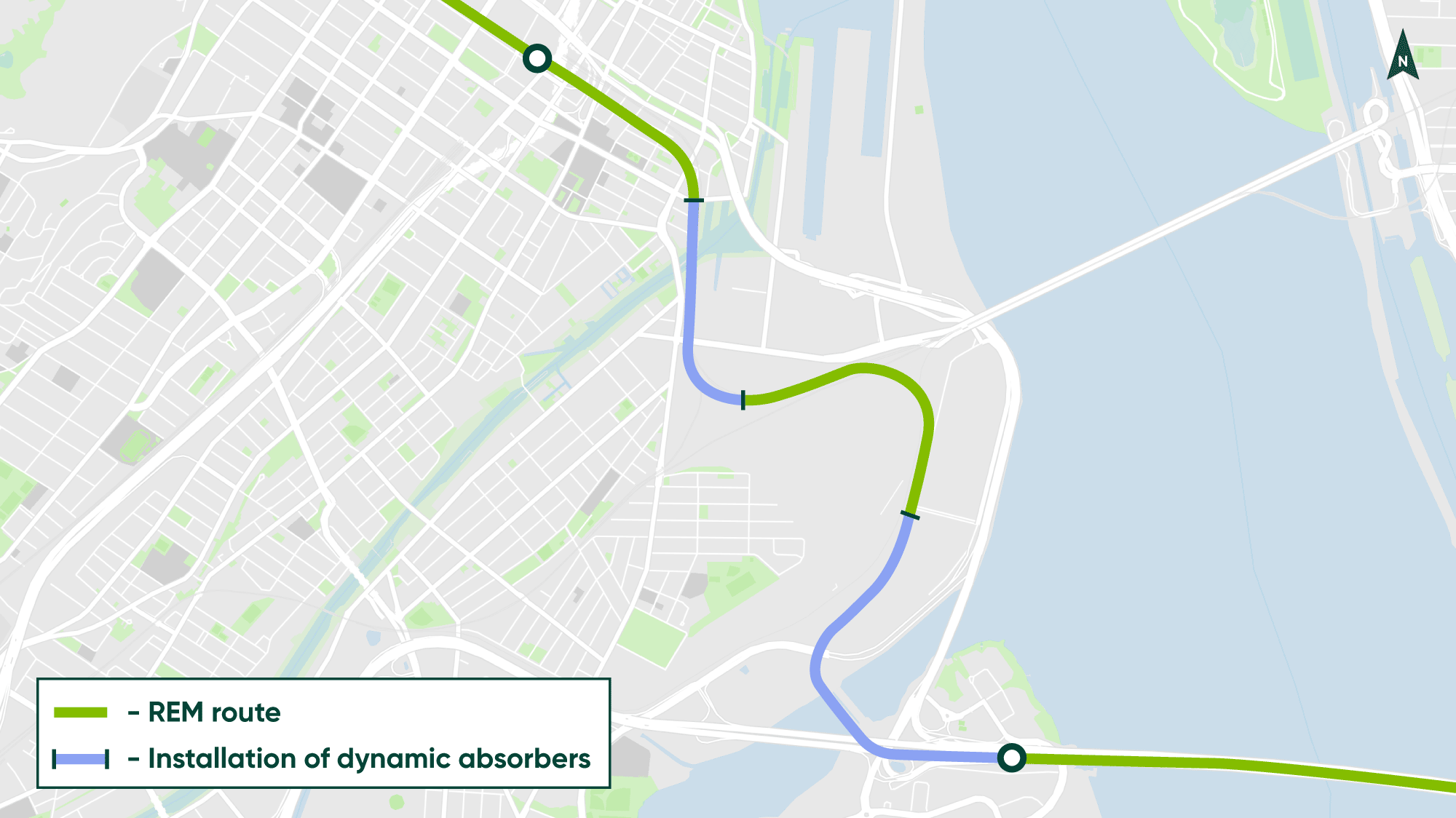

Dynamic absorbers

These systems dampen rail vibrations to reduce rolling noise. Absorbers were installed on a portion of the elevated REM tracks. According to SYSTRA’s analysis, this solution would result in an average noise reduction at source of around 2 to 5 dB(A).

Target areas for absorbers

Target areas for absorbers

Due to weather conditions, installation of the dynamic absorbers will not be completed until spring.

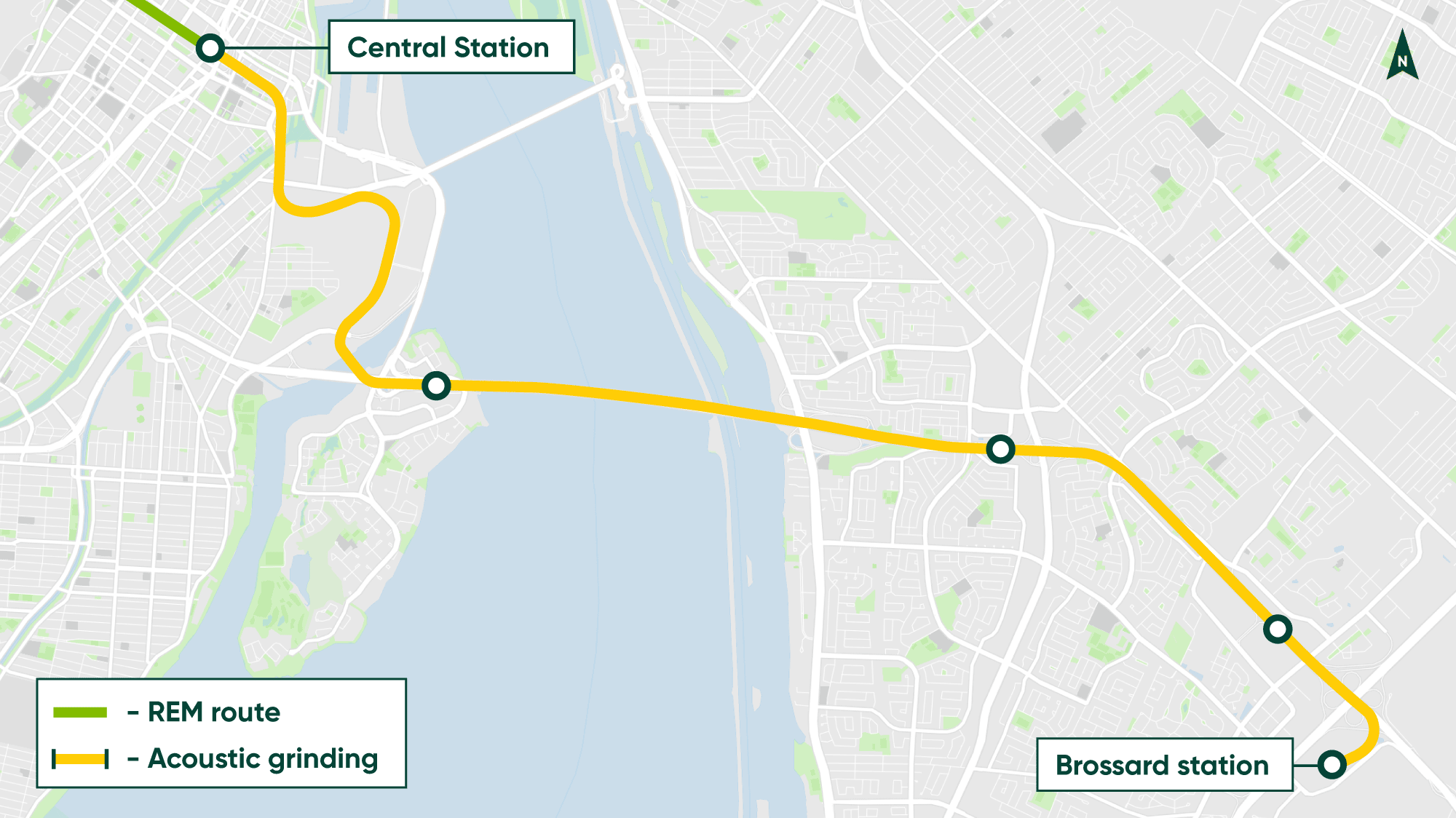

Acoustic maintenance

The rougher the rail and wheel, the more vibrations and noise they generate. The goal of acoustic maintenance is to grind (smooth) the tracks and reprofile the wheels, to make these contacting surfaces as smooth as possible and reduce noise while maintaining the grip required to keep the cars running safely. According to SYSTRA’s analysis, this solution would result in an average noise reduction at source of around 2 to 5 dB(A).

Area where acoustic grinding was carried out

Area where acoustic grinding was carried out

As part of the ongoing acoustic maintenance processes of the network, our teams identified variations in noise levels at the beginning of the year. An analysis was done and a maintenance issue (wheel reprofiling and greasing, etc.) on some trains was noted. Interventions are underway.

Conclusion and next steps

Based on the data presented, we conclude that the objectives for reducing noise from the passage of REM cars have been achieved.

When the two mitigation measures are combined, the objective was to reduce trackside noise by 5 to 10 dB(A), and the results obtained are of the order of 8 dB(A). Trackside noise reduction for grinding and reprofiling is 4 to 5 dB(A) depending on track configuration. The trackside noise reduction for dynamic absorbers is 4 dB(A) depending on track configuration.

Work to install dynamic absorbers in the Île-des-Sœurs station area will resume in spring. Following completion of this work, a confirmation of the noise reduction at car passages will be carried out and an appendix will be published and posted on the REM website in the Documentation.

The next step in managing this issue is to carry out a noise measurement campaign in the neighbourhoods this spring to confirm the impact of the measures.

Do you have any questions?

Contact our team for more information!